Для повышения удобства работы с сайтом мы используем файлы cookie. В cookie содержатся данные о прошлых посещениях сайта. Если вы не хотите, чтобы эти данные обрабатывались, отключите cookie в настройках браузера.

Machines

Wear-resistant valves

Valves and fittings

Gate valves

Last up to 9 times longer

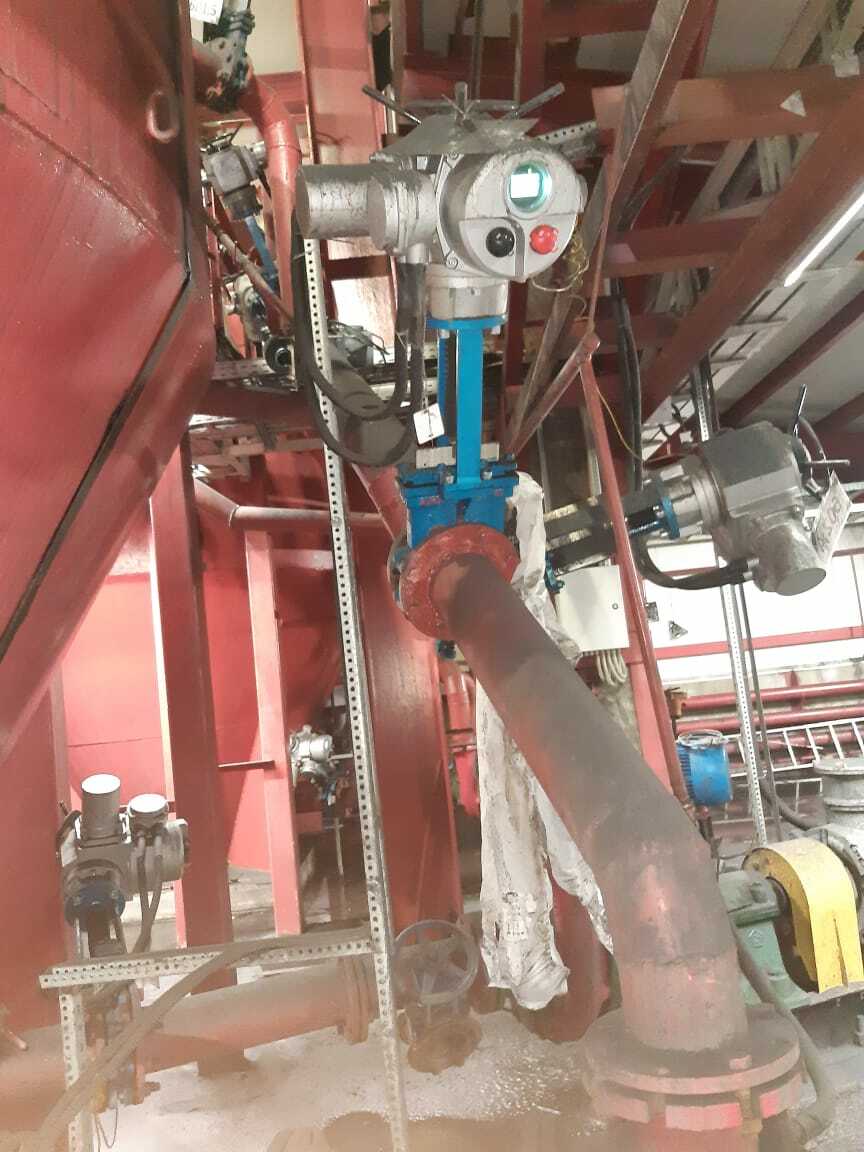

TAPP Group manufactures high-strength cast iron gate valves for abrasive media.

With Service life 4-9 times longer than other manufacturers' shut-off valves.

Their unique design, light weight, easy operation and high shutting and opening speeds make them a welcome piece of equipment for any beneficiation plant.

It is also possible to design and manufacture non-standard gate valves based customer requirements.

With Service life 4-9 times longer than other manufacturers' shut-off valves.

Their unique design, light weight, easy operation and high shutting and opening speeds make them a welcome piece of equipment for any beneficiation plant.

It is also possible to design and manufacture non-standard gate valves based customer requirements.

TAPP Group engineers have developed the IRONGATE gate valve, made of unique, abrasion resistant material. Its use has made it possible to create flow control valves with extended service life. The IRONGATE lasts up to 9 times longer than a typical stainless steel gate. Such systems allow clients instead of keeping a zoo of flow control valves use just one type of gate valves for different operating conditions.

Gate valves are made of high-strength cast iron or stainless steel. The body of the valve is protected by a wear-resistant ceramic insert that significantly improves impact resistance and overcomes brittleness problems of standard engineering ceramics.

For feed coarsenesses of 50 mm and larger, we install a metal ceramic guard, which allows the impact to be dispersed throughout the sleeve and keeps the ceramics intact.

To avoid wear on the stem, we cover it with a bellows, this ensures uniform lubrication and avoids contamination.

We manufacture flow control gate valves with manual, pneumatic, electric, hydraulic actuators, etc. The valve can be equipped with a positioner. It is designed to remotely adjust the gate valve opening percentage.

Gate valves are made of high-strength cast iron or stainless steel. The body of the valve is protected by a wear-resistant ceramic insert that significantly improves impact resistance and overcomes brittleness problems of standard engineering ceramics.

For feed coarsenesses of 50 mm and larger, we install a metal ceramic guard, which allows the impact to be dispersed throughout the sleeve and keeps the ceramics intact.

To avoid wear on the stem, we cover it with a bellows, this ensures uniform lubrication and avoids contamination.

We manufacture flow control gate valves with manual, pneumatic, electric, hydraulic actuators, etc. The valve can be equipped with a positioner. It is designed to remotely adjust the gate valve opening percentage.

At Severstal, an IRONGATE valve and a removable sleeve made of the same material lasts 9 times longer than Swiss-made counterparts. The coarseness of the pumped material amounts up to 110 mm.

Our IRONGATE valves are designed for flow control applications

TAPP Group manufactures high-strength cast iron gate valves. Their unique design, light weight, easy operation and high shutting and opening speeds make them a welcome piece of equipment for any beneficiation plant. It is also possible to design and manufacture non-standard gate valves based customer requirements.

The thickness of the valve seat and the gate itself with doubles flanges and bolt joints is 10% more than of similar products;

Additional IRONGATE valve protection is perfect for flow control, it can be fitted to any gate valve

Replaceable body protection made of wear-resistant CUMI ceramic.

Valve body protection can be made in polyurethane;

Valve body protection can be made in polyurethane;

The body seat provides wear resistance due to special heat treatment;

Anti-corrosion treatment of the casing both inside and outside to protect it against corrosion;

Principle of actuation

With manual feed adjustment:

They are used in positions where manual feed adjustment is required and pose a great alternative to automatic feeders.

With automatic feed adjustment:

Automatic adjustment can be electrically, pneumatically or hydraulically actuated.

More:

It is possible to install a positioner to regulate the flow by controlling the closing/opening level of the gate valve.

They are used in positions where manual feed adjustment is required and pose a great alternative to automatic feeders.

With automatic feed adjustment:

Automatic adjustment can be electrically, pneumatically or hydraulically actuated.

More:

It is possible to install a positioner to regulate the flow by controlling the closing/opening level of the gate valve.

Valves and fittings catalogue

Gate valve

Designation:

P - Pneumatic actuator, stainless steel gate valve, without positioner;

PP - Pneumatic actuator, stainless steel gate valve, with positioner;

PS - Pneumatic actuator, IRONGATE, without positioner;

PSP - Pneumatic actuator, IRONGATE, with positioner.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

PP - Pneumatic actuator, stainless steel gate valve, with positioner;

PS - Pneumatic actuator, IRONGATE, without positioner;

PSP - Pneumatic actuator, IRONGATE, with positioner.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Electrically operated gate valves

The electric gate valve is equipped with a torque sensor. It is designed to prevent the engine from burning out if a piece of material gets in when the valve closes.

Designation:

E - Electric actuator, stainless steel gate valve, without positioner;

EP - Electric actuator, stainless steel gate valve with positioner;

ES - Electric actuator, IRONGATE valve, without positioner;

ESP - Electric actuator, IRONGATE, with positioner.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

EP - Electric actuator, stainless steel gate valve with positioner;

ES - Electric actuator, IRONGATE valve, without positioner;

ESP - Electric actuator, IRONGATE, with positioner.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Manually actuated gate valves

Designation:

M - Manual actuation, stainless steel gate valve;

MS - Manual actuation, IRONGATE valve.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

MS - Manual actuation, IRONGATE valve.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Gate valves with

manual gear drive

manual gear drive

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Gate valves

with hydraulic actuation

with hydraulic actuation

Designation:

G - Hydraulic actuator;

GS - Hydraulic actuator with IRONGATE.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

GS - Hydraulic actuator with IRONGATE.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Pneumatic throttle

with a positioner

with a positioner

Designation:

D671X - pneumatically actuated throttle.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Throttle valve

with an electrical actuator

with an electrical actuator

Designation:

D971X - Electrically actuated throttle

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Gate valve

pneumatically actuated

pneumatically actuated

For environments with a solid content of up to 100 g/liter, replaceable polyurethane protection is installed.

Designation:

PPoli - Gate valve with polyurethane body protection, pneumatic actuator.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Manual butterfly valve

wafer-type

wafer-type

Butterfly valves are designed for pumping treated water with solid content up to 40 g/liter.

Butterfly valves have simple construction, good sealing, but high flow resistance.

Lining is available to extend the service life of the unit.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Butterfly valves have simple construction, good sealing, but high flow resistance.

Lining is available to extend the service life of the unit.

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Manual flanged double-leaf valve

Designation:

D41X - Manual flanged double-leaf valve

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Working pressure: Up to 10 bar

Diameter: From 50 to 1800 mm

Advantages

-

DesignSimple and reliable design of gate valves from TAPP Group simplifies installation and operation

DesignSimple and reliable design of gate valves from TAPP Group simplifies installation and operation -

Leak-proofHigh degree of integrity even when operating in aggressive and chemically active media

Leak-proofHigh degree of integrity even when operating in aggressive and chemically active media -

Service lifeRobust design and purposed materials ensure a long service life

Service lifeRobust design and purposed materials ensure a long service life -

VersatilityGate valves can be used in any industry

VersatilityGate valves can be used in any industry

Do not hesitate to contact us for the equipment setup and configuration.

For inquiries, you can contact us via WhatsApp at the phone number below or send us an email.

Phone (WhatsApp): +7 (910) 320 27 52

Email: info@tapp-group.ru

Phone (WhatsApp): +7 (910) 320 27 52

Email: info@tapp-group.ru

By clicking the submit button, you accept the user agreement

Awarded as the best business of Russia in 2018, 2019 and 2020.

An exclusive partner of AURY in Russia

450

Realized

projects

projects

80 companies use our equipment

10 times faster

4 hours for PPR.

4 hours for PPR.